These improvements to the processing of scrap steel comprised of larger more efficient and higher capacity furnaces. Understanding Electric Arc Furnace Operations.

The Electric Arc Furnace Part 3 Operation The Graphite Network

Designed for Specific Needs GEs design is based on decades of experience expert calculations and CAD tools.

. Tamination from the furnace lining. The electrical aspect deals with the furnace power requirement to make it functional. Electric Arc Furnace Process.

Electric arc furnace 17 4 Conclusions Electric arc furnace-based steelmaking is the low-CO2 alternative to make steel as long as scrap is available at a competitive price. The compact design makes it easier to seal the furnace for improved energy recovery from the process gases. This great variety of our designs is described below.

When the liquid material is poured into a mold depend-ing on the mold design fairly large crystals can result. Third STC Furnace to Grand Blanc Processing USA. In the electric arc furnace process the electric arc furnace oxidizing slag is firstly produced when the iron scrap is melted and refined into steel and then the electric arc furnace reducing slag is produced in the ladle refining furnace.

In this regard numerous models have been presented to describe the electric arc 1-10. Many fur-naces many features. Process is lower compared to the open arc process.

Carbon Dioxide Sequestration in Cementitious Construction Materials. Design of an experimental electric arc furnace 1992. By Hartman Alan D.

In 1975 EAFs accounted for 20 of the steel produced. There is a broad variety of steel scrap both in terms of composition from plain carbon steel through to highly alloyed tool steel and geometry from finely shredded sheet through to. Some twin shell furnace operations are achieving tap-to-tap times of 35 to 40 minutes.

The advancement of any nation technologically has been influenced and elevated by the extent to which it can usefully harness and convert its mineral resources. Snam and Tenova together for Decarbonization. A 100T furnace would process the scrap in about an hour using a transformer of 60MVA capacity.

GE offers electrical arc furnace power transformers that are precisely adapted to thermal mechanical and dielectric constraints. Introduction EAF a very energy- n. 200 Malibongwe Drive Private Bag X3015 Randburg 2125 South Africa Keywords.

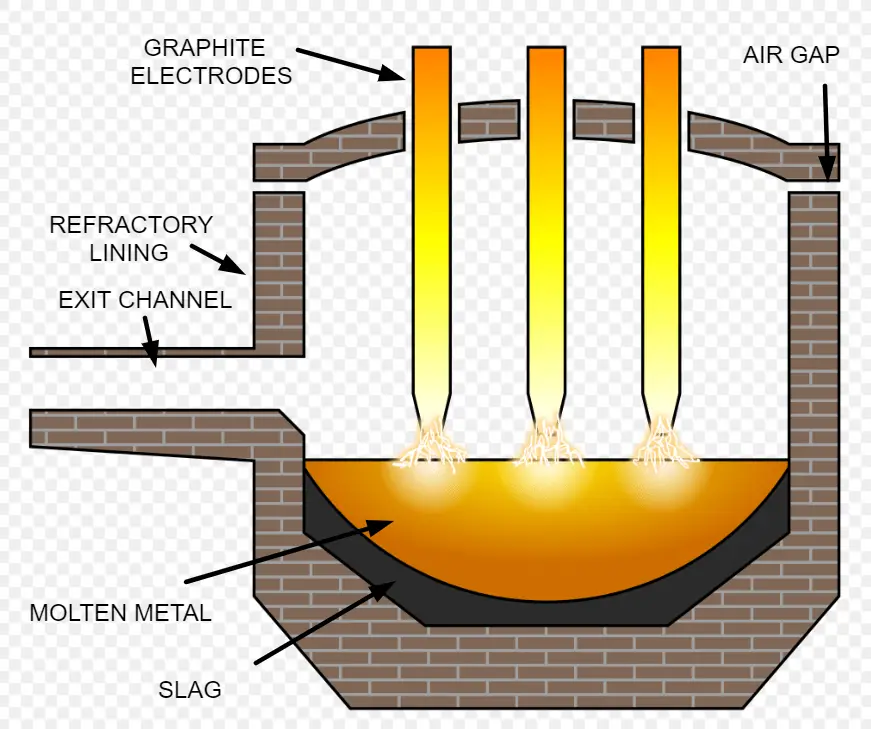

2 Introduction to Electric Arc Furnace Steelmaking 21 Basic Concepts The Electric Arc Furnace EAF is today the most common way to recycle steel from scrap. New Corporate Website for Tenova. Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes.

DC ARC FURNACES PAST PRESENT AND FUTURE Rodney T. Electric arc furnace technologys other main benefit lies in crystal size which can have a significant impact on the finished productparticularly in grinding materials. An electric arc furnace was designed and constructed to melt approximately 5kg of steelcast iron scraps using locally produced Soderberg electrodes.

SMS SIEMAG Submerged-Arc Furnaces and Electric Smelters 8 A WIDE RANGE OF DESIGN SERVICES We have designed a large variety of sub-merged-arc furnaces and electric smelters adapted to suit the individual requirements of the customer. Get free access to the library by create an account fast download and ads free. The Second World War saw a steep increase in the use of these furnaces leading to the modern Electric Arc Furnace design operation and working principles.

1 Introduction Electric arc furnaces EAF are electric process heating installations used for melting processes with the heat produced by an arc burning between the electrode and the charge. Therefore it is necessary to find a suitable model for electrical arc furnaces. The more compact furnace design the higher powerdensity and the far lower electrical loss in the furnace secondary system compensate for this increased energy loss.

Tests carried out showed that it. Still this process route may advance in lowering emissions through the spreading of several technologies that are already available and working at industrial scale. PDF - 73793 KB Laser tracking and tram control of a.

Mentioned factors exact and complete design of the power system with arc furnaces should be performed. Instabilities in electric steelmaking furnace arcs cause electrical and acoustical noise reduce operating efficiency increase refractory erosion and increase electrode usage. Download Design Of An Experimental Electric Arc Furnace Book PDF.

Electrical arc furnaces especially for very high load currents. Download full Design Of An Experimental Electric Arc Furnace books PDF EPUB Tuebl Textbook Mobi or read online Design Of An Experimental Electric Arc Furnace anytime and anywhere on any device. Celsa France Chooses Tenovas NextGen.

Electric arc furnace Furnace transformer Secondary circuit Stress calculations Temperature calculations. Machine learning methods provide a powerful forensic examination of industrial processes. Basic parameters in the.

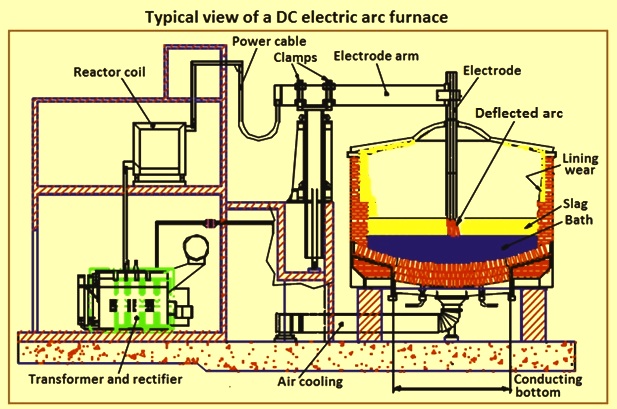

PDF - 73793 KB File Type. The following features of our furnace design are implemented to improve the silicon recovery. STEEL ELEcTric Arc Furn AcE Anode Mixes Our Solutions for DC Electric Arc Furnaces Hearth mixes in the anode area of DC electric arc furnaces fin pin billet conductive bottom are exposed to extreme conditions.

By 1996 the figure had risento 39 and by the year 2000 or shortly Overthepast wo thereafter could approach 50. Pyrometallurgy DC arc furnace electric arc smelting Abstract DC arc furnaces were first used industrially for the reductive smelting of chromite fines to produce ferrochromium thirty years ago. The electric arc furnace has been the subject of extensive research due to its complex and chaotic nature.

Design of day bins and furnace bins to avoid segregation Rotating charging tubes Rotating furnace body. The design was achieved through consideration of relevant theories and their practical application. 6111 Power throughput and diameter for the DC arc furnace 243 6112 Electrical design of the power supply for the DC arc furnace 244 6113 Tap-hole spacing 246 6114 Summary of ConRoast furnace design specifications 248 612 Testing of Other Parts of the Process 250 6121 Roasting for sulfur removal 250.

The electric arc furnace operating cycle is called the tap-to-tap cycle and is made up of the following operations. RHI Magnesita DC bottom anode mixes show the highest refractoriness in the market that cannot be reached by competitors.

Electric Arc Furnace Industrial Efficiency Technology Measures

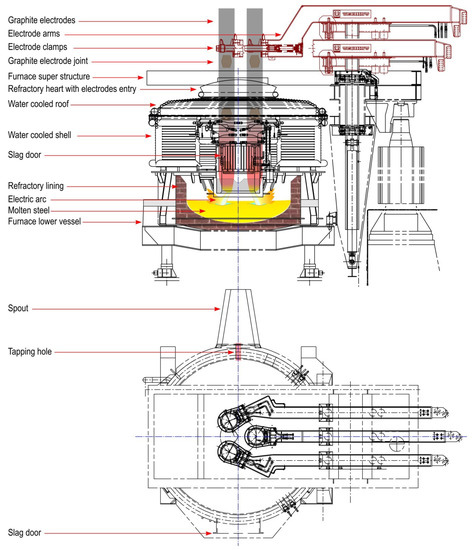

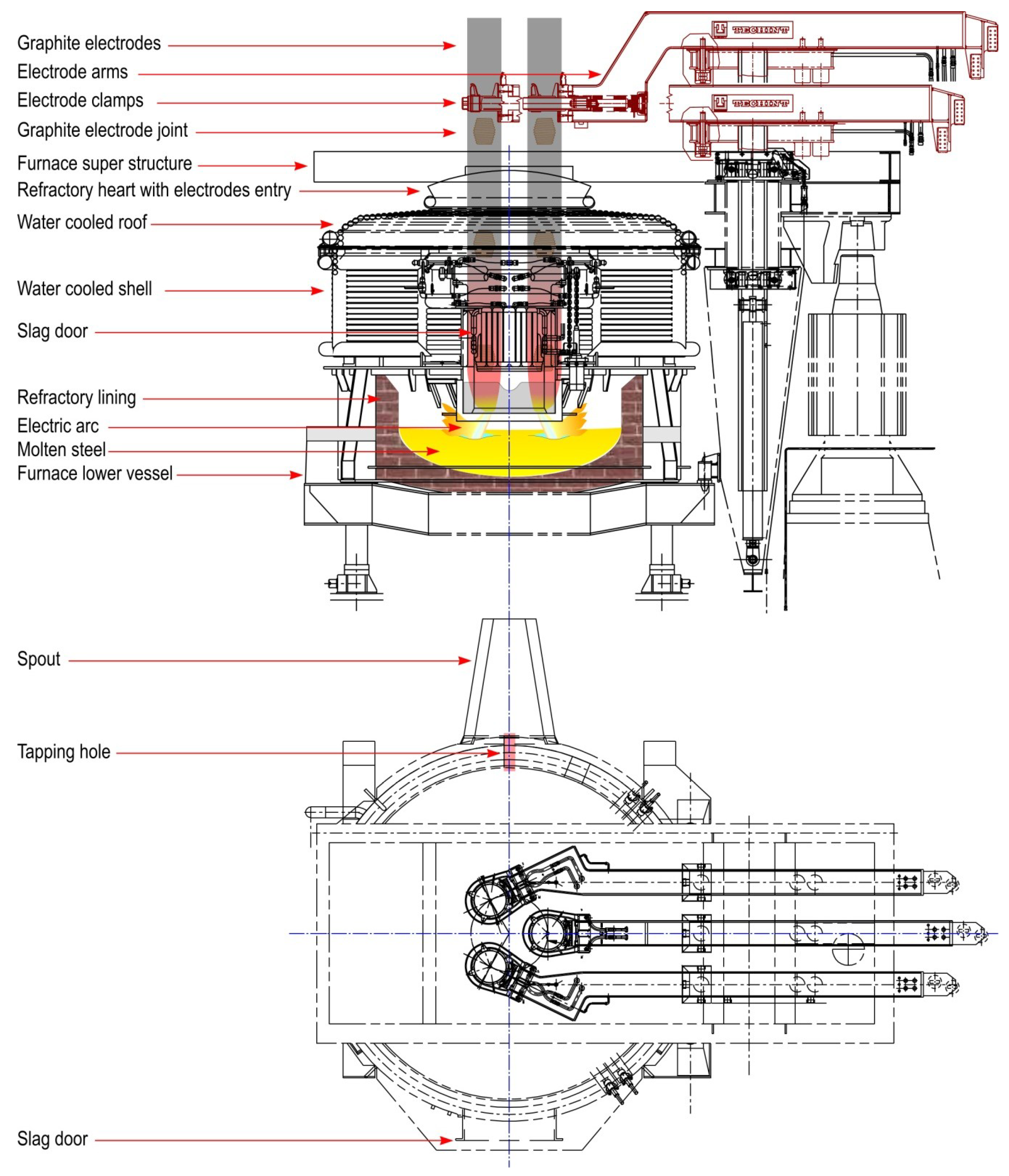

Design Features Of An Ac Electric Arc Furnace Ispatguru

Electric Arc Furnace Electrical4u

Energies Free Full Text Comprehensive Electric Arc Furnace Electric Energy Consumption Modeling A Pilot Study Html

Electric Arc Furnace Design Operation And Working Principle Bright Hub Engineering

Energies Free Full Text Comprehensive Electric Arc Furnace Electric Energy Consumption Modeling A Pilot Study Html

Dc Electric Arc Furnace Ispatguru

Electric Arc Furnace Definition Types Construction Working Application Advantages And Disadvantages Pdf Notes

0 comments

Post a Comment